December 2013:

As quick as possible after calving to the VMS

It is important that not only heifers but also older cows are milked as soon as possible after they have given birth.

The heifers feel as if they’re in trance after giving birth and will believe that they should be milked and all around belongs to it as well. Furthermore, the hormones will work quicker (which are needed for milk let-down and recovery from the calving, e.g. to let the uterus to shrink faster). It doesn’t seem to be pleasant but it’s actually very healthy. And the production is stimulated to start up. If it’s possible, these cows should be milked 3 times a day for the first few days.

The longer the heifer, but also the older cow, is not milked the harder the gets udder, the more painful and the more difficult milking empty the next time milking. It’s not always possible milking often but very important.

It’s also very important for udder edema etc..

You can compare it yourself to procrastinating about going to the dentist. If you keep procrastinating, it will be even more painful and you won’t want to go to the dentist. If you’re on time and you don’t experience any pain than you will go also earlier the next time.

The cow will also get a reward in the form of some concentrate.

This is why it is also very important having an easy overview to see where the fresh cows are in de herd! (Look at Tip of the Month from August 2013)

November 2013:

Tips before Startup with VMS

Recently a lot of new stalls have been built. It is good to see that many farmers have chosen for automatic milking.

At DeLaval you almost always get an “Integration book” or handout. The handout contains different tips for both the farmers as well as the technicians. Some useful tips for the farmer are:

– Begin with a maximum of 50-55 cows per VMS. Cows as well as the farmer himself must learn something new, starting with the robot full makes it much heavier. When the cows have all calved at least once, you may expand that number carefully.

– It is important that when you change the ration, for example full TMR, that in the weeks beforehand are slowly being phased out and the cows learn to eat and appreciate food from concentrate.

– Structural feed is very important for the health and especially activity of the cow.

So with sufficient structure in ration, the cow learns faster!

– All of the cows need to be hoof trimmed a month in advance. If you have a new stall or new concrete then it is recommended to trim 3 months in advance. Otherwise the trimmed hoofs are too thin and that causes problems.

– Even though we say that with DeLaval VMS can milk “every cow”, we still advise to prematurely say farewell to the cows that have no chance. These cows include the structural SCC, cows with bad legs that you have to walk and chase after now already. Also cows that have the rear teats in the ligaments are also difficult. As for the rest, you know your cows the best.

– Shave utter and tails a few days before starting.

– Make sure that when the start-up day comes you have no other attention seeking problems. The mechanic and the (in Holland and Germany) special Start-up team have enough to explain. It would be a pity if you don’t remember any of it.

– Provide an adequate amount of gates which bring a lot of peacefulness (if setup right) during the startup. Feedfirst needs a few gates less, color markers can be useful here.

This makes as well the cows as Farmer less stressful and then goes the day a lot easier and learns the farmer also more.

This al has to make that the farmers enjoyed the start-up day!

October:

Questions about possibilities, skills with VMS

Currently I visit more at dairies that work with the VMS of DeLaval for several years now, through the Vitality package and also through direct requests. These visits are useful because the dairyman doesn’t meet a lot of “broad-based sparring partners” on the overall herd management. You can accomplish a lot with the combination of a milking robot and a computer, this is a fact. Knowing that not everything is being used is also a fact.

A milking robot can’t do everything, it’s a machine and not a human being.

It also occurs that a dairyman, sometimes for years, just thinks that this is something he just has to deal with, but it doesn’t have to be that way!

What do you run into occasionally and what are your most frequent questions about VMS milking and its possibilities or impossibilities?

=> Put these questions on mail to harry@harrytuinier.nl

You have paid for the program, so you can also use it!

September:

Preventing too many three tits

By robot milking cows become easier a 3 teats milkers after they are too often not completely milked. For example kicking the teat cup off or slowly milking. When this happens oftener, the computer doesn’t recognize it as a problem. The computer just thinks this cow is not giving more milk, so the computer doesn’t give you a warning that the cow hasn’t been completely milked. For that to happen, the cow must give less than 50% of the expected yield. If that doesn’t quite reach the expected 50% the computer won’t give a warning.

When you see that a cow has not been completely milked yet and it is not named by the computer as incomplete, make sure that the cow is completely milked in your presence. Then you might be able to find the cause of it and you can make sure the computer learns again how much milk the cow should give.

Is kicking off the teat cups mostly the cause: see if you can change the teat cleaning, the type of teat dip (for softer teats), feed slower, pretreat more carefully or by increasing the time settings for “incomplete milking” (the cow then has a limp udder and hasn’t saved a lot of feed so she will be quicker irritated) or by simply turning that time setting off if the conductivity of the cow can have it.

Is the cow milking too slowly the cause, then go to the “Animal Card” > “VMS Settings” > “Configurations” and check the “Base take-off decision on lower flow”. You can also use the “Extended pre-milking time”. Mostly better works a “Clean Twice” Teat cleaning and use by “Feeding” the option of “consumption rate” to spread the concentrate over a longer time of her VMS visit. The cow will then be more inclined to give good milk.

Incompletely milked cows are also often cows with hoof problems, they aren’t milking very relaxed, not standing square and they are inclined to rub their painful hoof (mortellaro?) against the teat cup.

August:

Check activity fresh cows

Very important for a good start and lactation after calving is the healthiness of the cows, especially the first days after. For a good start and a good lactation, just the fitness of the cows is very important, especially the first days after calving.

A lot happens with the cow, she has just calved so she’s weaker, ration changes, group changes, which reorders the hierarchy in the herd. If she is going to give a lot of milk, her need for energy is higher.

In robotic milking the cow is milked more often, which can cause the milk yield to increase extra. This makes this period extra exciting.

To keep a close eye on the cows activity, there are dairymen who put a fluorescent colored halter around the cows neck for the first 10 days. You can then easily see where the cow is and if she is active enough, goes to the feeding barrier frequently, etcetera.

If you follow the cow activity closely, then choices that are made around topics such as concentrate or treatments, can be made much earlier.

In this period, the use of painkillers sometimes can cause a cow, especially a heifer, to go to the feeding barrier more often which makes her reach and pass the “dead center point” quicker, so that she can leave it behind her faster.

July:

Concentrate build up after calving

During my dairy visits I now often leave a report behind about concentrate buildup after calving.

It’s evident that this is a very important issue.

The best results are achieved when you fill in the report with a nutritionist who knows the qualities of your forage but who also knows the characteristics of the concentrate you’re using.

How this has to be used is what I spend much time on because guiding cows through their transitionperiod takes skills, is very profitable and expands the lifespan of the cows.

For cows that have no problem calving and who keep showing up at the feeding barrier afterwards, concentrate build-up isn’t difficult and a lot of usable knowledge is already available.

We keep in mind that cows that are about to calve eat less forage than usual but that she will eat more and more each day in the oncoming weeks. A cow and her rumen can than handle more concentrate without is having to get worried about rumen acidification, laminitis or a negative energy balance, etcetera. (see tip October 2010).

There are also cows that for example have calved too heavy, or who, for some reason, are too skinny at the start of the lactation, or who can’t walk comfortable, etcetera. Not being dried off in a good condition but certainly not having calved in a good condition. When these cows visit the feeding barrier insufficiently, then these are the cows where we would like to build up the concentrate less fast and where we certainly should be more careful with “faster” (grain) or high protein concentrates.

With heifers we are very careful with these concentrates, because, apart from giving milk, they still need to grow. (Having 10.000 kilograms of milk in 1 year is fun, but a lifelong production of 100.000 is better ;-))

On the list given, these cows are called “the difficult start” group. These are all the cows of which you think that the forage intake is minimal, the first days or weeks after calving. It is also possible that some fat cows are just too lazy or that they calved with edema or fat so they visit the feeding barrier not enough (too little structure compared to the energy in the dry-off time?).

I have made a category “Too fat and dominant” and with this we mean the dominant cows: these are the cows that take charge right away after calving, they push other cows away and usually they are on high production very fast after calving. You can build up concentrate with these cows faster than with other cows. Otherwise, these cows will lose productiveness after 40 days.

Of course, the goal is to get all of the cows back into the “healthy category”. Sadly, we don’t always have our livestock under control. But providing proportionally more structure instead of energy, more space to walk, to lie down and to move, manicured claws, correct Ca / P ratio and correct Cations / Anions during the dry-off period, will take many cows in the desired section.

Very complicated! Fortunately, with DeLaval you will have the possibility to easily make your own adjustments if things have not been going according to the directions…. Good Luck!

June :

Healthy Hoofs:

Hoof disorders are still one of on the largest expenses of a dairy. When milking a cow with a milkingrobot this is even more obvious because a cow must then independently think how many times she’ll have to go to the VMS and how often she goes to the feeding fence and drinking trough. Limiting because off claws will cost a lot of milk and lifespan!

Add to that fact that a crippled cow with never stand still in the VMS which makes it harder to align and will have to spend more of her time in the VMS. The farmer as well as the cow aren’t happy with that!

Important measures:

Hooftrimming: cows in different lactation stadiums, before dry-off time and at mid lactation. This should ensure that the cow walks as balanced as possible and to minimize cracks and crevices around the claws, because bacteria like Mortellaro e.g. love it! (See Tipp okt. 2011)

Places to lay: adequate rest so that the fat pad between flesh and hoof muscle is spared and the cow therefore will walk more resilient, more comfortable and thus longer. This is important for the blood circulation (read: purge) of course, special for the legs and the udder or injuries.

A cow needs to lay down, relaxed, on average 12-14 hours per day.

Foot bath: would be greatly recommended if you have the possibilities of offering this on a regular base to your animals

Smooth exercise lanes or large passing options: because of white lane defects

Exercise lanes dry and “clean”: having a scraper system in place that does not transfer bacteria back and forth from the milking cows to heifers/calves

Rubber on the floor: especially with dry cows, for example in a single-row barn where they have to turn short, these cows often weigh 100kg more. and at places cows walk much or turn short.

Ration, 2/3 of the total dry matter: contains structure-holding forage, very important short after calving. A nice smelling portion hay works miracles. Of course, the cows further in lactation and dry cows an even larger part of the textured ration

Be careful with the protein and “fast energy”: such as grain products because of laminitis. This is shown after about 4 to 6 weeks after the feeding error has been made.

May:

Service Timer:

In the Computer from the VMS is a Service Timer, which most of you dairymen will know.

This will be used, for example, to know at which time to change the liners etc. Whoever has feeding on automatic program with accurate parameters will regularly need to check the list “Ration calculation log”. Whoever has the feeding manually will need to check the feed quantities every 2 to 3 weeks.

Once a month by Batch edit => checking “Batch VMS Animal Settings” ensures that the VMS will treat your cows like you want them to be treated and that old settings or adjustments won’t stay the same for the cow’s life.

Also, for example, shaving hair from udder or burn, calibrating feed or other important matters that you must not forget are handy when you are told by the Service Timer that you should not forget them.

We are people, we can think, but also we can forget. A computer never has to think and because of that will never have to forget! That is inclusive old settings as time notifications.

You can customize the Service Timer under “Monitoring and Control”.

Add your important things that you should not forget with the “new” button.

On the Monitor Board you will see notifications when something has to be done or happen.

When you have put yourself some new Timers we see you more like to watch which are overdue and that makes you and the system work better 😉

April:

Drying off cows without antibiotics?

Drying off cows without antibiotics has a few large advantages:

- It saves money and it provides flexibility using less medicines or in a different way

- If you don’t treat the animal, you will not harm the healthy udder

- The cow stays sensitive to penicillin so that she will be easy to treat if an udder inflammation occurs with the next lactation.

It is and will always be very risky, to dry off a cow without antibiotics and that’s also the reason why it is important for you to have a clear image of which cows have a larger risk of having an udder inflammation. A cell amount of 100 doesn’t say much because that’s an average. It can happen that 3 teats have 20 and for one teat, most of the time with very little amount milk, is over 1000!

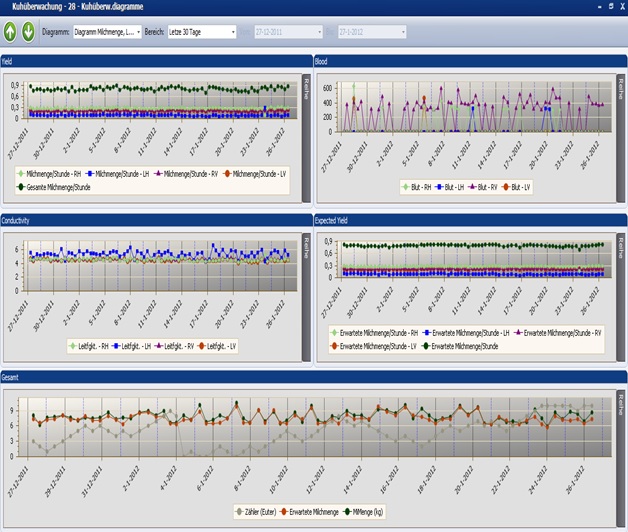

With the cow monitor and the graph behind it, you have a clear review about how the lactation of a cow in that area of production and the healthiness of the udder has turned out. It is so clear that you can choose the teat you want to evaluate. This is without a conductivity measurement or having something like that almost impossible!

If you see anything special, then a setting-dry period is extra dangerous!

Look for the “to-put-dry-cow” on the cow monitor. Double-click so that you see a graph.

Choose “Yield, conductivity & blood graph” (down below) and then select 365 days.

On the graph at the right you see that the cow with the left back quarter, probably doesn’t have an udder inflammation but that it is subclinical and gives the least milk. Also the MDi, at the bottom, moves to much from the top to the bottom, like a wave and it stays like that.

If you see this graph pull up on your screen you will know what you have to do.

Of course it is very important to work hygienically, and always keep the dry cow in a clean and spacious area to spend her time being dry.

March:

Drinking space per cow

Provide enough room to drink, about a 10 cm drinking trough per cow. Make sure the drinking troughs are well placed. We know that a cow that has just come out of a VMS is thirsty, causing her to eat more forage than with a dry mouth. A cow that has just calved is also thirsty!

The place where the cows drink from their troughs should be a calm place. In a stable the preference goes to passages where a cow feels safe, not a place where a more dominant cow can push other cows in a corner. If this is the case, that a more dominant cow pushes a low ranking cow against the fence, then a low ranking cow will only drink when needed and most needed. Or not use the passage.

In conclusion: the best place to put a trough is at the end of the passage that guides the cow away from the VMS, in the birthing box or a place with enough room for the cow to move.

Of course, these drinking troughs and places should be easy to clean. You could also get pre-cooled water which tastes better for the cow but is more prone to bacteria.

If you have, for example, 60 cows, it would be best to have 3 drinking troughs with the length of 2 meters each.

February:

Many dairy farmers with a milking robot also have a concentrate station or debate whether one is needed.

We may not expect a cow to eat more than 8 kilograms concentrate in the VMS.

Most cows even find that to be too much.

So if, in the long run, more concentrate is needed to keep the cows production at a maximum level, you have 2 options: A larger ration with maybe more “extra” products along the feeding fence, or more kilograms of feed in the concentrate station (or a little of both).

A standard ration with extra products can make the ration along the feeding fence taste better, which was special interesting this year when most grass was less tasty. On the downside, cows can take a long time to select what they want to eat and because of that they will not eat the ration you calculated them to eat. Especially the low ranking animals or the cows that have a hard time coming out of the transition period, have problems eating your calculated ration and will eat when the most delicious food is gone and is not reaching the full amount energy or percentage structure.

A standard ration with supplements can easily become too high for the cows at the end of their lactation thus causing it to be expensive and giving you lazy or to thick cows. A concentrate station is often more convenient, you give it only to the cows that need it and the cows that are at the end of their lactation are easier to feed the right amount. Of course you also have the chance that the cows will come less to the VMS.

Again, the correct settings make the difference, so small portions in the concentrate station, keep an eye on how often the cow enters the VMS, will they only come in 2 times a day or maybe 4 times a day? Especially after calving the first time gradually build up the concentrate in the VMS and then build up in the concentrate station. If she is more than about 150 days in lactation or if she under a certain milk weight than put only concentrate in the VMS! Those are some things which make the concentrate station to a big value or no added value!

That supplement products may fit well is a fact, see the tip from December 2012, but that it also adds more waste and work is also known, so the results in accountant reports are almost always less attractive than you have calculated ….

January:

Milking Permissions.

At DeLaval VMS the farmer can set what the right moment is that the cow gets permission to be milked.

Especially the first months of her lactation to be milked more than twice a day is really a “must” for the high yielding cows. (Just ask women with newborn babies). It is also one of the major advantages of robotic milking. For end lactating cows it is not good that they are milked often.

When You start miking with VMS first time all cows are set to get Milking Permission after 6½ hours. And that is a good start setting. Also new cows / heifers are set on 6½ hours and have to be checkt by you on Automatic Milking Permission.

So how should the Automatic Milking Permission be set?

The Delpro program divides the lactation into three periods. This can be found under “Farm” => “Automatic Milking Permissions”. The first period the “Early Lactation” period is immediately after calving, the period that the cow has to be milked frequently. That is also very good for stimulating hormones, instincts and activates milk vesicles. This can easily give 10 – 15% more milk!

The first period may last until the time when most of the cows get their lactation peak, usually around 60-80 days. Since Delpro 4.5 we have a very clear graph from your farm for it.

In the early lactation period, the time setting is more important than the expected milk yield and we put on 5-6 hours. For that period, we set the permission for expected yield at the level at which the cows give their top production divided by 4. For example, your average heifers have as top in their lactation 28 – 30 kg per day, then we set the expected milk yield at 7-8, older cows average peak at 36 – 40 kg milk => put expected yield on 9.

In the second period, the “Mid Lactation” period is the story of hormones and instincts much less important.

In this period the declining production actually provide a noiseless falling visitor behavior. This is also close to natural behavior. So here is the “expected yield” most important! With this period we play a lot more and look:

- how many cows do you have on the robot,

- how are the teat lockers,

- what is the production in that period,

- how long you have been working with the VMS (Do all cows have calved one or more times since you started with the VMS ?)

So that is not easy!

As soon as after the start-up a correct expected milk yield is known (after approximately one week) you put the second period at 7 hours with the same expected milk yield as in the first period. Then we look at the above points and first flip up the hours, step by step after a few month. At 8-10 hours. The next step is to obtain the expected milk yield to turn up. That is not so necessary when there are not so much cows on the VMS.

A rule of thumb for this is: what gives your heifer / cow around 120-150 days in lactation and that we divide by three.

Then, the expected milk yield setting is mostly 1 kg higher than in the first period.

Did you say 40 or 70 cows on a VMS? That makes a big difference and with a full robot has the mid laktation period to be put higher dan with 40 cows on.

Or 6.000 or 10.000 kg milk per cow per year?

The third period, the “Late Lactation” period is really for the last 2 to 3 weeks before drying off, no more than 2x a day milking: We put that at 10 hours and a very high expected yield. So then the hours are most important again.

Note that after 70 days, and especially in the second half of lactation, cows milking more than 3 times a day, eventhough they give much, it’s not good for the resting of the cow, the teat lockers and in total not good for the length of life from your cows!

(High average visit does do only well at birthday parties or farmer meetings …….)

It is also not good for the capacity of the robot and acidity in milk.

And gives more incomplete milkings.

Adjustments must be made in small steps in order to keep as much as possible, the cow in its rhythm.

You do have the option for an individual cow to set separately, e.g. a high SCC cow more often or a cow with little milk or narrow teats milk less frequently.

With free cow traffic means the cow may be milked, at Feed First it means the cow has to be milked and therefore at Feedfirst the Automatic Milk Permissions may be set slightly higher.

ample, after a disinfection can is empty, to rinse the whole system. Take off the nozzle and the (milk) filter in the can and flush the system with warm water. After that put a new filter on the weight in the can and the disinfection system works perfect again.

ample, after a disinfection can is empty, to rinse the whole system. Take off the nozzle and the (milk) filter in the can and flush the system with warm water. After that put a new filter on the weight in the can and the disinfection system works perfect again.