December:

Udder hair shave

It is surprising how fast hair currently grows on the udder!

On our “Work routine” list is written that it is advised to burn or shave hair on the udder every two months.

In the fall and winter, because hair grows more quickly, it is advised to shave or burn the hairs more often.

It is also suggested that you shave all of the hair on the tail and plume with what hangs on it. (That is often the cause for a “dirty” cow, which is also not hygienic, and dirt goes everywhere)

It is also advised to wipe the camera lens with a cloth containing descaling liquid.

This will result in quicker connections, and makes the cow and thereafter the manager being happier.

Good descaling liquid always needs to work itself in, so make sure to let it sit for a while!

Do not immediately wipe off and rinse.

November:

Teatcup centre

The teat cup and also the pretreatment cup, fit perfectly if they go up right under the teat.

The distance from teat cup to camera is programmed.

If this is not quite the required 100% then the connection with a good teat position goes well. However, a cow with angled teats or teats of another abnormal state does not connect as well.

So, pay good attention if the teat is in the center and above the cup if it needs to connect properly.

If it is not sufficient, go to the touch screen and go to VMS Menu => Robot => Calibrate (third tab) execute “center cup”.

Otherwise, contact your mechanic.

October:

Separation milk with too much blood:

Milk which consists of too much blood can automatically be separated. You can activate this setting by going to the Cow Card, then VMS Settings and selecting Automatic Diversion.

What is too much blood? Only when values are indicated above 1000, the discoloration is visible to our eye.

A cow with colostrum milk, for example, easily reaches 3000 or higher.

Many farmers do not utilize this setting. Because, the milk of a colostrum cow they separate anyway.

However, a bruise, for example, by a blow from another cow or simply a vein blood spatter, also gives a lot of blood in the milk. And we’d rather not have that in the milk tank.

You could than consider to fill in the “Udder blood threshold”. To set it for an udder you always have to deal with dilution if it’s one teat. That is why it is the best place to fill it out, for example 2500 or higher.

At teat level, it is “dangerous”. An abundance of blood could be in a teat where there is very little amount milk. And then, all the milk from this cow will be separated.

Check the cow monitor to see from which cow you will not have milk in the tank. Then you know which level is for you too high.

By Batch Edit => Batch VMS Animal Settings it is easy to activate for all cows.

For every new cow you have to think about that later.

September:

Teat cleaning cup:

The Teat cleaning cup from DeLaval is often one of the reasons to choose DeLaval VMS.

The method of cleaning and stimulating:

“It polishes like my mother and encourages like the calf,”

is what the designers had in mind, and it turned out perfectly.

We must admit that we have not always cleaned as consistently in a milking stall and certainly not stimulated as consequent as our teat cleaning cup does.

And the dirt and the first rays are always separately drained from the milk collector.

But does the teat cleaning cup get the chance to deliver an excellence job?

- Is the outside also clean so the cup can’t move dirt and bacteria around?

- Is the rubber head not worn or torn?

- Does it make enough and firm strokes?

- Is there no kink and no tension on the hose?

- Does it sometimes miss a teat, or often?

- Is there too much space on the gripper?

- Is the water temperature good?

It is wise that you take it daily out of the cartridge and clean it.

Then there’s minima bacteria and dirt on it, and in the same time you check that “your employee” can deliver true craftsmanship!

August 2015:

Are black teats a problem?

Of course, black teats have their disadvantages.

But:

- Hair on the udders do too;

- A dirty camera does too;

- Lime scale on the camera does too;

- A dirty or worn sponge does too;

- Deviating teat shape or an abnormal udder shape does too;

- A narrow teat shape or a milk vein right along the teat does too;

- Cows with hoof problems are moving all the time;

- Technically seen, a bad VMS, extra space on the arm or that it moves to slow or too fast does too;

- The manure plate that doesn’t work well also has its disadvantages;

- Cows that have little room or too much room in the VMS does too;

- Old, or too big liners do too;

- To many flies do too.

One disadvantage is OK for the VMS, 2 or 3 can be OK to but it has to stop at some point…

Some cows simply have certain characteristics and there’s not much we can do about it.

If we can minimalize or deplete some of the disadvantages which are in our hand, we can make that as few as possible cows have problems .

We want, and can achieve the lowest number of incomplete milking’s!

So black teats or abnormal teats …, it isn’t a problem immediately but if it is a summation than it certainly will become one!

July 2015:

Match the hot weather.

Cows create sodium bicarbonate in saliva and thus good ruminating is therefore very important.

Both the creation and rumination decreases in hot weather like this past week.

Even rapid breathing caused by hot weather affects the production of bicarbonate.

That is why an extra addition to the ration in this weather is very useful!

Also, what you have learned about the quantity of drinking water: during warm days like these cows might drink 30-50 liters more!

Do you have plenty, clean water ready at their disposal?

June:

Many milkings between 20 – 100 days in laktation

When you decided to go for (a) robot(s) one of the reasons was probably that fresh cows can be milked more frequently.

We also think that fresh cows, e.g. cows between 20 and 100 days, be milked at least 3 times per day.

Do these cows on your farm reach the expected amount of 3 times a day?

It is very easy to check, for example in the list under “Milking Info” at “Milking Performance”.

We come across differences in dairies. Some have more than 4 milking’s for this group while others can barely have 2 milking’s. And all with the same robot brand..

A sick, weak, lame cow, fresh calved, or you know why, may have less than 3, no one else.

If there are too much, for example 5 out of 20, then we must look for the cause.

It often has to do with rumen fill or puncturing of roughage. So the operation of your roughage ration, or proportions.

But it can also, and perhaps in relation with the previous one, have to do with the hooves.

Also, it could be that there are too many of saturating feeding the ration. Or they can get so much at the feedfence they don’t need the concentrate in VMS.

And it may have to do with the stable layout, e.g. small waiting area, narrow walkways, on the place of the VMS is no fresh air, or to many flies, etc.

Or are the settings around milking permission not good?

Or is the robot too full?

Ask yourself which excuse your cow can make to go the robot less often…!?

May:

More kick-offs this year?

It seems that this past year more cows and heifers are being annoying in the VMS than other years. Heifers also seem to have more edema this year than previous years. Make sure that these animals don’t receive a ration that is too generous/rich or get too much salt before they calve, and if it is possible at all give them more space for exercise.

Notice if they are from the same family, or have the same dad.

When they come into the robot and they are annoyed, there are some possibilities: Even though we find precleaning at DeLaval great, we might need to postpone it for these animals (for example: a week).

If needed put the milking cups on manually the first few times. The next step is that you also manually attach the rear cups and let the machine do the front cups, but if the cow is calm than let the VMS attach all the cups. It is very important for these animals, especially when edema or a hard udder is present and is that they are being milked three times a day!

A full udder is then very painful and they connect the pain with the VMS so they will not to go to the VMS again if they get hurt!

Note also that liners and preparation cup are good. Maybe you could even let the feed come a little slower (from 100% back to 75%) so that the cows are kept busy a little bit longer with the food while being milked.

April:

Fly nuisance

It’s getting warmer again!

Are you ready for it?

So are the flies!

Not only are flies a nuisance during milking, they can also easily transfer diseases. What do you do to combat flies?

Some dairymen use maggot control on their grids, or hire a professional to inject the walls with chemicals.

A fan above the VMS could also freshen the air.

Cows love some wind in the summer, flies hate that!!

Fresh air around the VMS would improve conditions nonetheless.

If what you are doing is helping, don’t be hesitant to share your ideas, it could really help other dairymen!

March:

Easy daily cleaning

Do you have, within reach, water (cold and warm) spray, cleaners, (carwashing) brush and kitchen towels close behind your robot? Then chances are that the visit time per cow in the VMS declines by 30 seconds compared to those who don’t have cleaning materials within reach.

robot? Then chances are that the visit time per cow in the VMS declines by 30 seconds compared to those who don’t have cleaning materials within reach.

The equipment at hand invites you to keep the important parts clean, even if you are busy. And that invites the VMS to “do its very best!”.

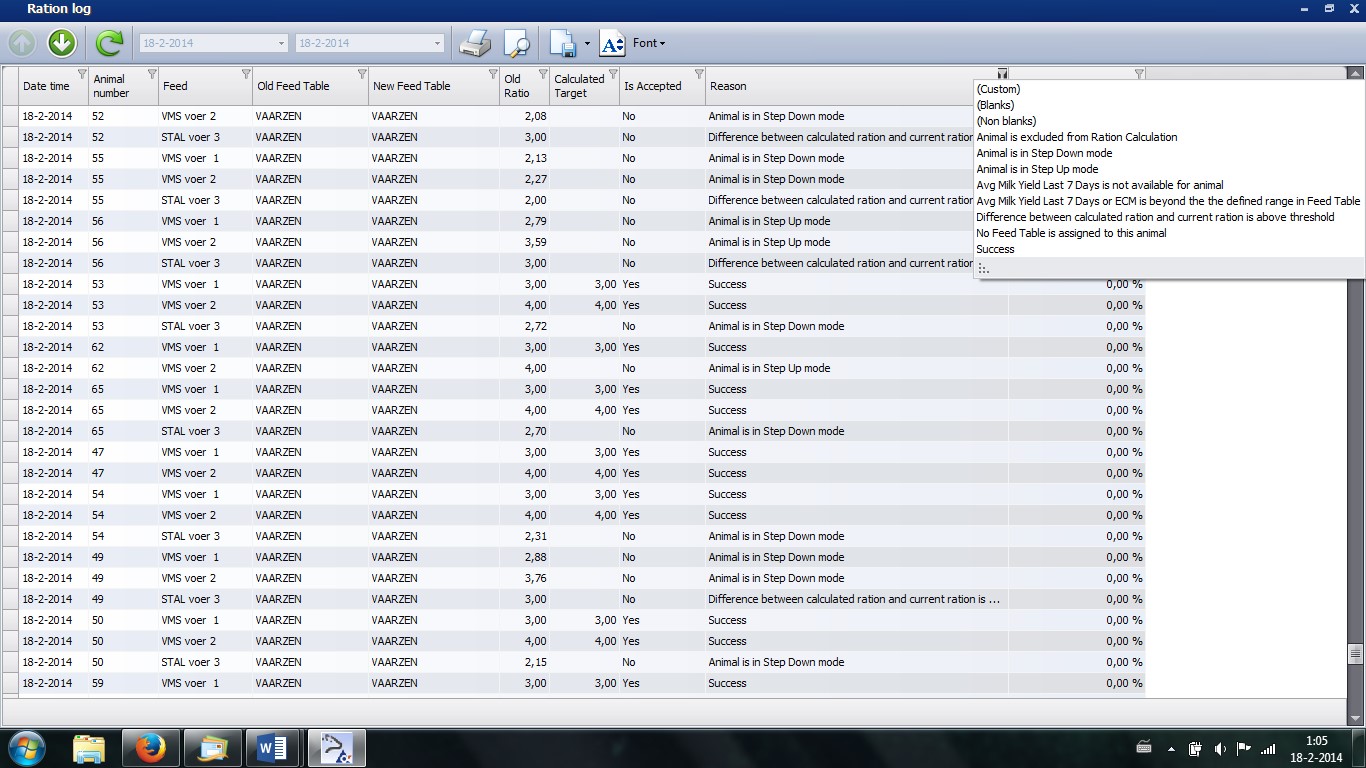

February 2015:

Feeding settings, your choice how: Range from 0% automatic to 100% automatic

In Delpro the options in regard to the concentrate are extensive.

You now have the choice to full manually insert a concentrate amount, automatically 0%, to fully automatic, 100%, fed by Delpro. At 100% automatically feeding the computer assumes that all cows are equal, but you know better!

Hence, many farmers actually opt for a way between, semi-automatic. Then the cows that should have minimal modifications, the concentrate adjustments are done by the computer but the cows which need a larger adjustment will result in the computer asking the farmer to allow this adjustment or not.

It always start with inserting good feeding tables that fit the other ration appropriately.

Building up concentration after calving is always done best manually. (SEE T.O.T.M July 2013)

After ca. 50- 60 Days in Lactation you can manually check but also let the computer adjust the concentrate amount, for example every 7 days and only to the cows whose change isn’t greater than i.e. 30%. (Feed Table Parameters)

A cow that needs special treatment can be excluded from the automatic ration calculation. This is done by selecting “Exclude from automatic ration calculation” on the cow card.

It is for some cows wise to manually adjust the concentrate amount due to condition, setting her dry soon, diarrhea, etc.

These cows are so long excluded from automatic feed calculation until you unselect, so you should not forget them!

That is also the reason that when you check the Loglist on different Concentrate amounts you should also immediately check which cows are on the list and why. (Reports => Default Reports => Feeding => Ration Calculation Log)

You can do that most conveniently in the log list by clicking on ˜Reason” in the blue filter (funnel) top right hand side on the screen/window.

That is where you can see all of the possibilities. If you press “Animal is excluded from ration calculation” for example, you can see which cows are currently excluded. Or which are still building up or decreasing.

January 2015

Saving Power

On your dairy farms are a couple of “power consumers” who deserve attention.

For example the cooling unit, which is not always on a place you walk past daily.

Sometimes the cooling louvers are full of dust or dirt. Maybe the air filters aren’t clean. If this is the case, the cooling capacity could decrease by 30 to 50 percent which means the unit will have to turn on more often.

This results in a higher usage of power and also more wear and tear.

Also the compressor can, unnoticed, consume more power than necessary.

Since DeLaval switched over to more hydraulic system, the compressor doesn’t have be turned on as often. That clearly saves a lot of power.

But if, along the way, there’s a small leak somewhere or pressure is being tapped for something else, you will have to be extra alert for leaks.

Most of the time you don’t notice when the cooling unit or the compressor starts more often.